Sewer Shield® Composite Certified H20 Loading Corrosion-Resistant Manhole Inserts

Uses:

Sewer Shield® Manhole Inserts when properly installed will act as free-standing manholes as the old manhole decays, and will not be affected by ground-water or other chemical attack from inside or outside of the insert.

Surface Preparation:

Hydro blast to remove loose materials

Installation Procedure:

Sewer Shield® Manhole Inserts are easy to install. Bell & spigot assembly allows for easy alignment of the sections, and the adjustment section and walls can be readily cut with carbide-edged power tools to adjust the heights or allow for penetrations. Sewer Shield® 100 is applied as a putty between the bell and spigot sections, as well as for bonding the inserts to existing piping systems. Since no single section weighs over 600 lbs., they can easily be set into place with a small crane or backhoe.

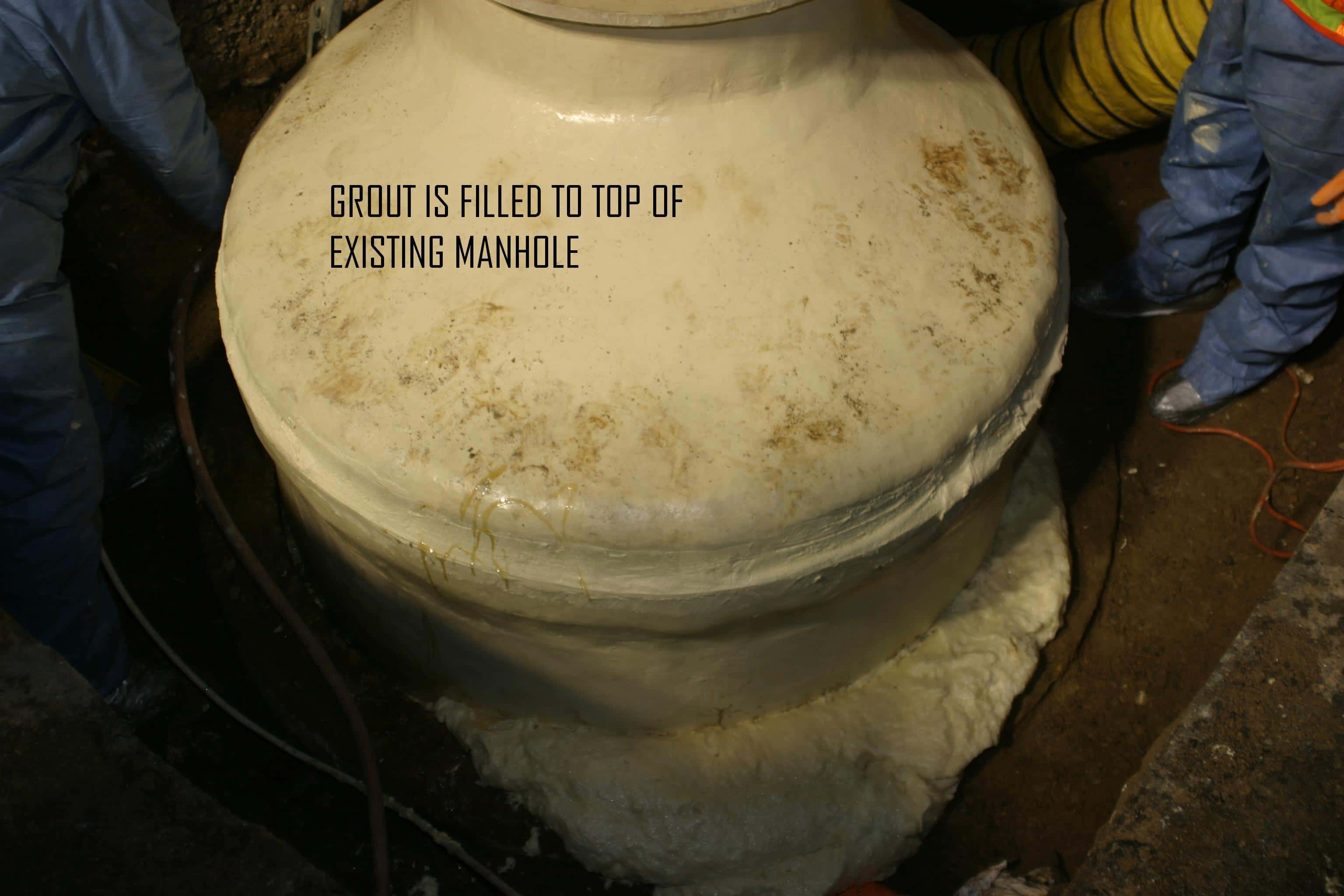

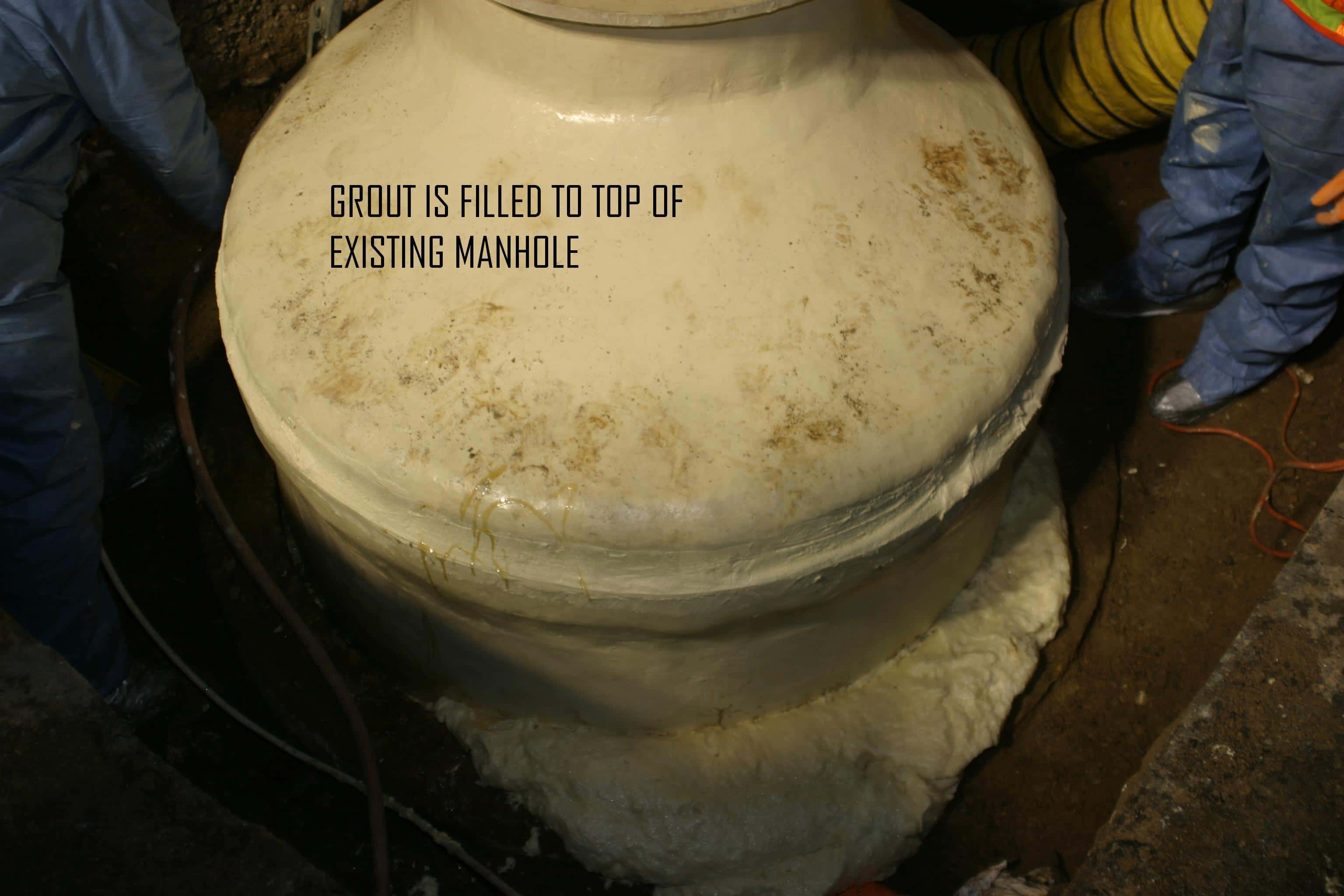

To install the new insert, the top is cut off the old manhole, and the interior is hydro blasted to remove any loose materials. A Sewer Shield® grout is poured around the bottom edge of the old manhole prior to lowering the first 5 ft. section into place. Spacers are used to align the insert within the confines of the old manhole.

As each 5 ft. section is set in place, a hydrophobic grout is poured between the insert and the existing manhole wall to fill any voids between the insert and the existing wall.

As the sections are stacked, a Sewer Shield® putty is applied to both the bell and spigot to provide a seal between the sections, and the excess material is wiped from the inside seam to provide a smooth finish. Once the sections are assembled and the adjustment section has been trimmed to size.

The composite Sewer Shield® top manhole access section (flat or domed) is nested on top of the vertical insert wall.

The composite Sewer Shield® spacer ring and steel manhole cover are then set in place, the top is backfilled, the pavement is repaired, and the manhole is back in service.

Packaging:

Sewer Shield® manhole inserts come in three basic parts:

1. Cover section (concentric, eccentric or flat)

2. Riser sections (typically each 5′ high to facilitate installation)

3. Sewer Shield hydrophobic grout and putty

The composite Sewer Shield® top manhole access section (flat or domed) is nested on top of the vertical insert wall.

Customer Service:

For any questions you may have in regard to Sewer Shield® manholes and manhole inserts, please contact us

Printable version here.

| Material Properties at 75° F. | |

| Tensile Modulus | 1.57 x 106 |

| Shear Modulus | 0.362 x 106 |

| Poisson’s Ratio | 0.22 |

| Tensile Strength, psi | 18,700 |

| Flexural Strength, psi | 32,000 |

| Density, lb/in3 | .054 |